Understanding the Ice Maker System in Your Samsung Bottom-Freezer Refrigerator

A Samsung Fridge with a bottom freezer is designed to provide convenient access to frozen goods while maintaining optimal temperatures for fresh food storage. One of its key features is the built-in ice maker, which offers a steady supply of ice cubes for your household needs. To ensure efficient and reliable operation, it’s essential to understand the components and processes involved in the ice-making system. This includes the water inlet valve, fill tube, ice mold, ejector arm, and control board, all working together to transform water into ice and dispense it when needed.

Common Reasons Why Your Samsung Bottom-Freezer Fridge Isn’t Making Ice

Clogged Water Supply Line or Filter

The first step in troubleshooting your Samsung fridge’s ice-making issue is to check the water supply line and filter. A clog or blockage in either component can prevent water from reaching the ice maker, leading to a lack of ice production. Over time, mineral deposits, debris, or even a faulty filter can obstruct the flow of water. Regularly replacing the water filter according to the manufacturer’s recommendations and inspecting the supply line for kinks, damage, or signs of freezing can help maintain a clear and uninterrupted water supply.

Malfunctioning Water Inlet Valve

The water inlet valve is a critical component responsible for regulating the flow of water into the ice maker. If it becomes stuck, damaged, or fails to receive the proper electrical signal from the control board, it may not open, preventing water from filling the ice mold. To diagnose a faulty valve, visually inspect it for signs of corrosion or damage, and test it with a multimeter to ensure it’s receiving power and properly opening and closing. If necessary, replace the water inlet valve with a genuine Samsung replacement part.

Defective Ice Maker Components

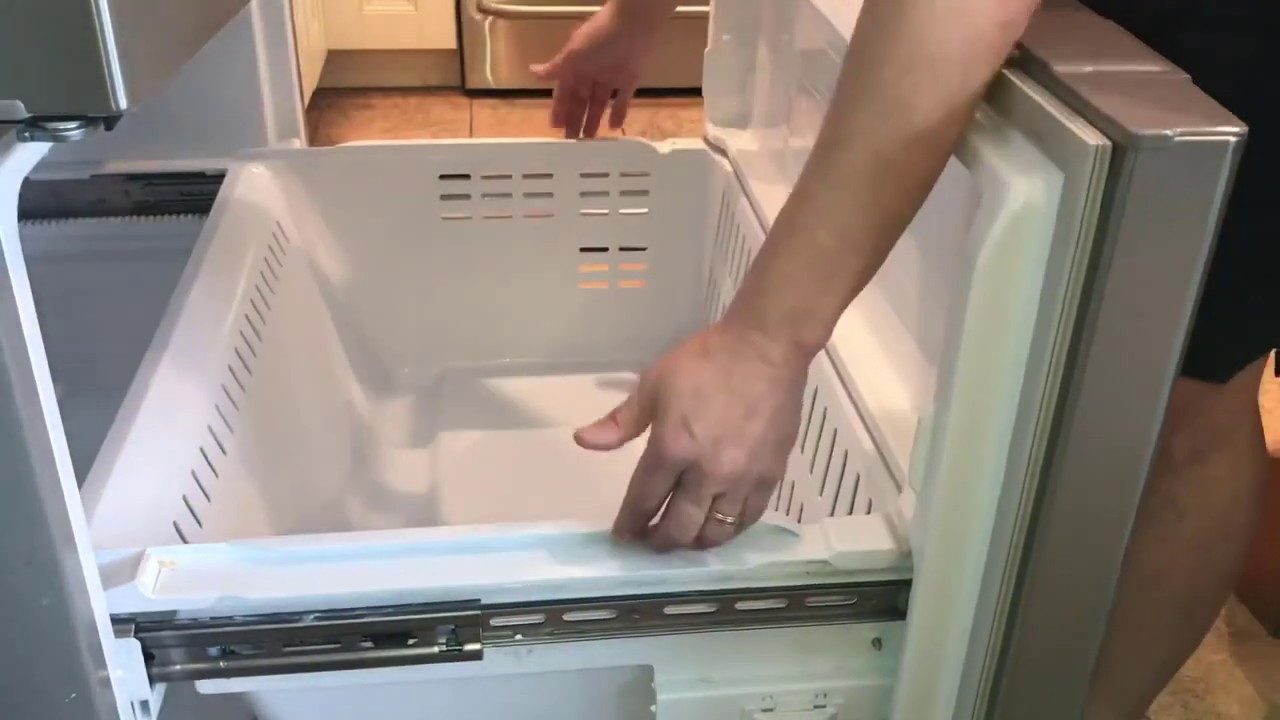

Problems with the ice maker itself can also cause ice production issues. The ice mold might have a crack or leak, preventing proper water containment and ice formation. The fill tube could be frozen, blocking the passage of water. The ejector arm might be stuck or malfunctioning, hindering the release of ice cubes. Inspect these components for visible damage, clean them if necessary, and test their functionality. If any parts are found to be faulty, they will need to be replaced to restore ice-making capabilities.

Advanced Troubleshooting Techniques and Professional Assistance

Checking the Control Board and Electrical Connections

The control board governs the ice maker’s operation by sending signals to various components, such as the water inlet valve and the motor that drives the ejector arm. If the control board is defective or has suffered electrical damage, it may not properly communicate with these components, causing the ice maker to fail. Inspecting the control board for signs of damage, checking its wiring connections. And testing it with a multimeter can help identify any underlying issues. If the control board is going to find to be faulty, it should be going to replace by a qualified technician.

Seeking Professional Repair Services

While some ice-making issues can be resolved through DIY troubleshooting and repairs, others may require the expertise of a professional appliance repair technician. Complex electrical problems, hidden leaks, or issues involving sealed refrigeration systems should be addressed by trained professionals to ensure safe and effective resolution. If you’ve exhausted basic troubleshooting steps without success, contact Samsung customer support or a local. And certified appliance repair service for assistance.

Preventative Maintenance and Best Practices for Optimal Ice Maker Performance of Samsung Fridge with Bottom Freezer

Preventative maintenance and following best practices are essential to ensure optimal performance, longevity, and efficiency of your ice maker. Here’s a comprehensive guide to help you keep your ice maker running smoothly:

-

Regular cleaning and sanitization

- Interior: Clean the interior of the ice maker, including the evaporator plate or grid, at least once every three months (or more frequently if used heavily) using a manufacturer-recommended cleaner or a solution of warm water and mild detergent. After cleaning, rinse thoroughly and dry completely.

- Water reservoir and lines: Descaling is necessary to remove mineral buildup in the water tank and supply lines. Use a commercial descaling solution or a vinegar and water mixture (follow manufacturer instructions) every six months or as needed, depending on water hardness.

- Ice bin: Empty and clean the ice bin regularly to prevent bacterial growth and unpleasant odors. Use a food-safe sanitizer or a baking soda and water solution.

-

Filter maintenance

- Replace water filters: Change the water filter according to the manufacturer’s recommended schedule, typically every 6-12 months, or when the indicator light signals. A clogged or expired filter can reduce ice production, affect taste, and lead to mineral buildup in the machine.

- Inspect external water lines: Ensure there are no kinks or restrictions that could impede water flow.

-

Check and clean air vents

- Clear any debris: Regularly inspect and clean the air vents to prevent dust and lint buildup, which can obstruct airflow and affect the cooling process.

- Ensure proper clearance: Maintain at least 1-2 inches of space around the unit to allow for adequate ventilation.

-

Inspect and maintain components

- Door gaskets: Check door seals for cracks, tears, or looseness. Replace damaged gaskets to prevent cold air leaks and ensure proper sealing.

- Condenser coils: Clean the condenser coils (usually located on the back or bottom of the unit) annually or as needed with a soft brush or vacuum attachment. Dirty coils can reduce efficiency and cause overheating.

- Hinges and latches: Lubricate and adjust as necessary to ensure smooth operation and proper sealing.

-

Follow usage guidelines

- Do not overload the bin: Excessive ice can block the sensor, preventing the machine from producing more ice until it’s going to empty.

- Use high-quality water: Hard or contaminated water can lead to mineral buildup, reduced ice production, and poor taste. Consider using filtered water or installing a water softener if your water quality is poor.

-

Scheduled professional maintenance

- Annual inspections: Have a qualified technician perform a thorough inspection and maintenance service annually, or as recommended by the manufacturer. They can address any issues, replace worn parts, and ensure optimal performance.

- Warranty compliance: Keep records of maintenance and repairs to maintain warranty coverage.

By following these preventative maintenance and best practices, you’ll help ensure your ice maker operates efficiently. And produces high-quality ice, and enjoys a longer service life.

Conclusion of Samsung Fridge with Bottom Freezer

In conclusion, addressing ice-making issues in your Samsung bottom-freezer refrigerator involves a systematic approach. And starting with understanding the ice maker system, identifying common causes of failure, and employing advanced troubleshooting techniques when necessary. By following these steps, seeking professional assistance when needed. And and practicing regular maintenance and best usage practices, you can effectively resolve ice-making problems. And ensure your Samsung fridge continues to provide a steady supply of ice for your household.